Project Description

Berolina-CIPP | Kiama Bends, NSW

Overview

The NSW Roads & Maritime Services (RMS) had identified that two x 60m / 900mm corrugated steel culverts under the Princes Highway at the Kiama bends that needed to have their structural integrity reinstated.

Downer PipeTech completed the structural renovation of these corrugated steel culverts using a fibreglass reinforced structural lining system supplied by BKP-Berolina of Berlin, Germany, that is cured using ultra-violet light. This sets a new first for the application of this product in Australia.

The challenge

The Kiama Culvert Lining project had a number of challenges associated including access restrictions, host pipe defects, and the corrugated steel pipe material which was severely corroded in many sections.

In addition to the site challenges, the client required a fully structural solution with a minimum 50-year service life whilst minimising the loss of bore.

The area was also sensitive from an environmental perspective so it was important that the lining process did not contaminate downstream creeks or streams.

The solution

Having considered all possible options, we opted to use the CIPP Berolina liner system. This fully structural pipe lining solution sets new standards in pipe rehabilitation due to its high strength, long service life, cost effectiveness and installation methodology with minimal site footprint.

The liner is constructed of corrosion resistant fibreglass and polyester felt impregnated with high-grade vinyl ester resin which are set in an over-lapping arrangement.

This provides the product with very unique stretching properties during calibration, which allows it to fit tightly into difficult profiles such as corrugated steel. The wall thickness required to achieve standalone structural strength compared to typical felt and resin liners which only use the felt purely as a resin carrier is much thinner due to the reinforcement materials used in the liner manufacture.

For this project, we used a portable UV curing unit which required minimal site footprint which was easily wheeled into place.

Following cleaning and preparation of the host pipe, we installed a pre liner or gliding foil which ensured the uncured liner material would not be damaged during tow-in.

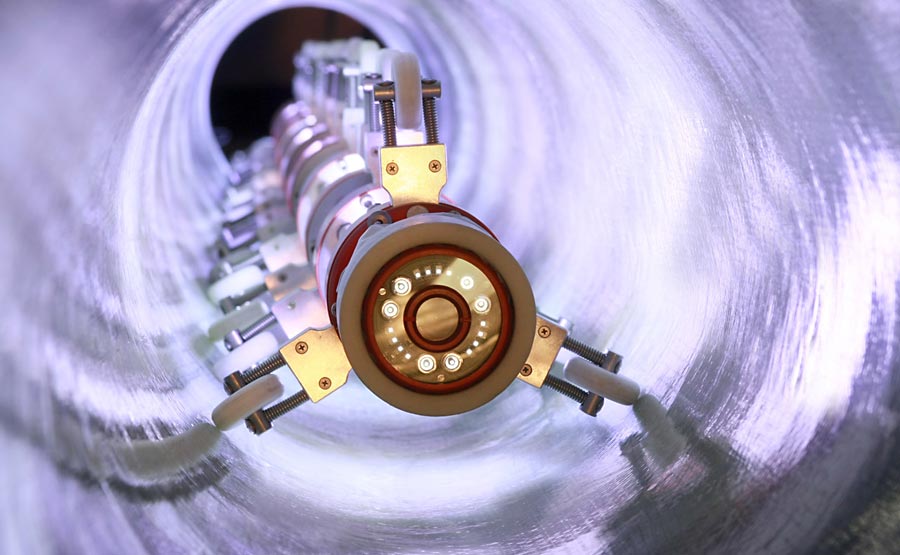

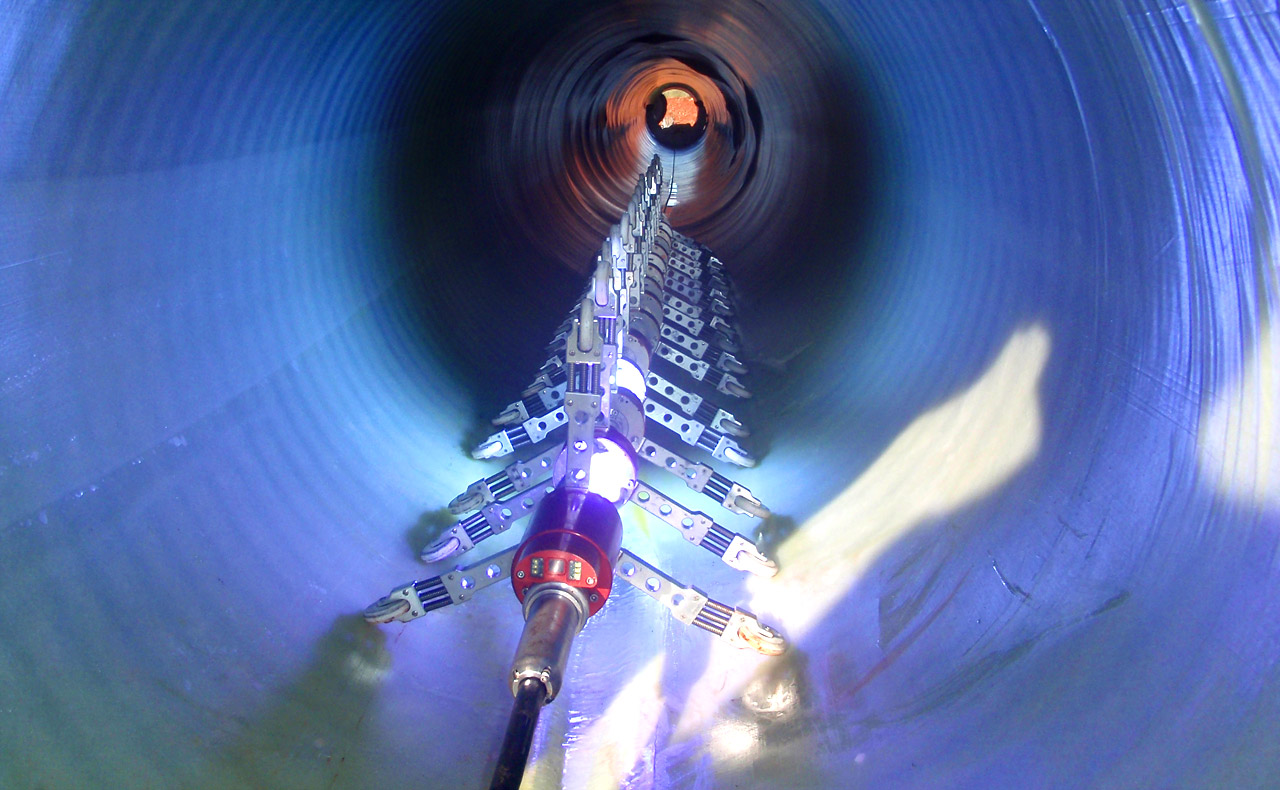

Once in position, the liner was fitted with end packers, inflated and calibrated to tightly fit the host corrugated pipe profile. Following calibration, the UV light train was inserted for curing. The curing process is fully controlled, which means the recorded data can be supplied to the client on completion as part of the QA documentation together with the liner manufacturer’s quality record.

Once cured, the ends were trimmed, the liner inner film removed, and the rehabilitated culvert immediately returned to service.

The outcome

The entire process from start to finish took 6 working days and given the large catchment area that these culverts service, the shorter working timeframe allowed a return into full operation before any significant rainfall events.

From the ensuing CCTV footage, the clearly defined corrugations and quality of finish was proof that Downer PipeTech had achieved an outstanding outcome. It also demonstrated the suitability of this technology for the renewal of corrugated steel culvert and pipelines up to 1.5 metre in diameter and sets a new benchmark for culvert lining solutions in Australia.

In summary, RMS now has a very smooth, tight fitting, abrasion and chemically resistant structural liner which will provide for a minimum 50-year service life.