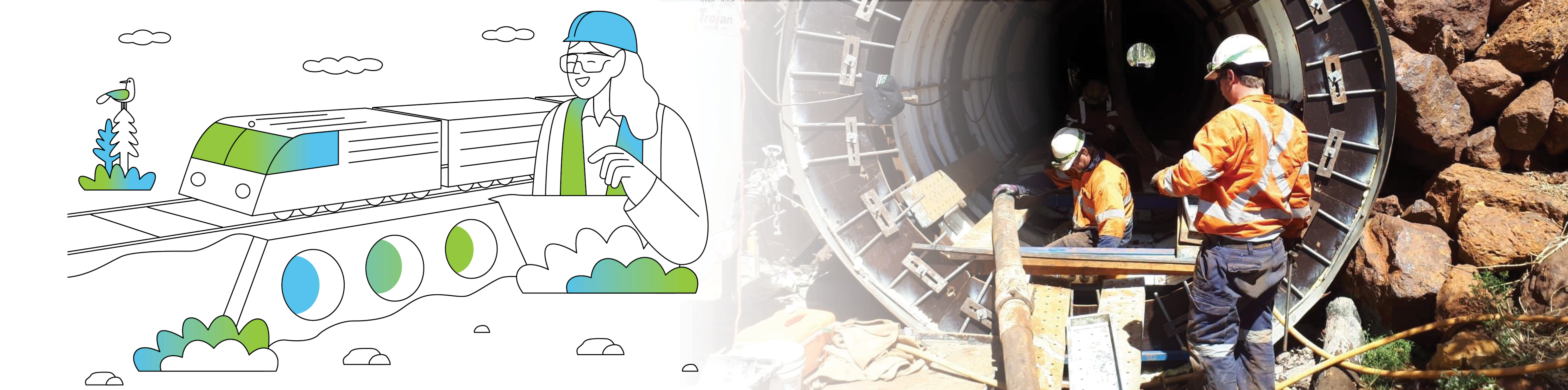

Downer PipeTech provides our proprietary TUNNELINE® structural reinforced-concrete lining system, the unique and versatile system for structural remediation on pipes, culverts and tunnels with a design life of more than 100 years.

This award-winning system is a simple, in-situ reinforced concrete lining technique designed for difficult-to-access sites and has a very low environmental impact.

Application

The Tunneline pipe system is a ‘cast in place’ lining technology that is delivered under pressure into a modular rigid steel formwork, using self-compacting concrete mixes.

When the shutters are removed, the internal finish is similar to that of pre-cast factory units, and in most applications leads to more efficient and improved flow characteristics despite hydraulic loss.

Tunneline is designed under either AS3600 or AS5100 together with AS3725 standards to provide an independent structural element or can be as a composite element inside brick and concrete structures.

Benefits

- Significant time and cost savings

- Does not require any advanced pre-works or stabilisation. Holes, cracks or missing masonry do not need to be repaired prior to installation

- Can be constructed inside any existing man-access structure regardless of shape, or access.

- Suitable for any host format ranging from 1200mm upward.